CREATION & PRODUCTION OF KNITTED FABRICS WITH EXPERTISE, FLEXIBILITY AND CARE FABRIC.

INNOVATION EVERY DAY MADE WITH TRADITION.

It all started in Aleppo, Syria many years ago when the company operated a textile production of size. Our journey brought us to Cairo, where we today in second generation produce what we do best, namely the finest knitted fabrics for those looking for the special thing.

We are proud to work on the development and production of fabrics every day, learning, trying out new techniques to produce and offer innovation to our customers. Our team of 200 colleagues is composed of design, technical and management staff, merging technical know-how with creativity and innovation culminating in the creation and production of a unique collection.

Our fabrics are a unique merge of experience and trend, integrating both, classic and innovative design concepts, to create a unique collection.

Today, we feel more than ever that our clients need individual advice, tailor-made solutions from design to finishing. We consider our clients to be part of the family, jointly working on the best possible concept for a very special and top-quality product.

Our design is driven by creativity and emotions but with a close eye on the functionality and durability of the fabric. To achieve this, we operate a vertically integrated production process, encompassing design, knitting, dyeing, finishing and quality control - knitting fabrics for tomorrow.

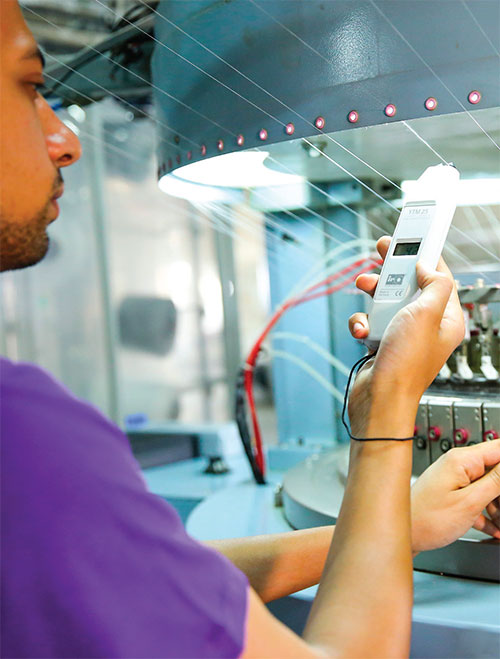

Machine preparation and setting are integral parts to ensure the perfect elasticity and colouring of the fabric. So is the constant monitoring and the flawless controlling of quality throughout the production process.

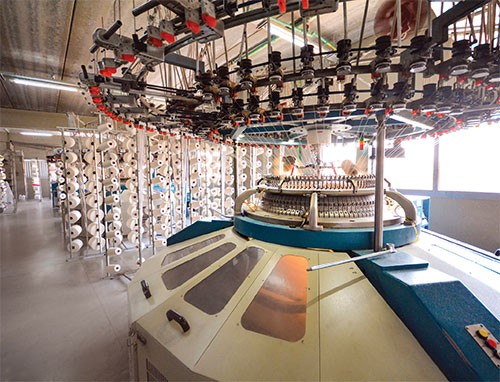

On 17.000 square metres we accommodate three main manufacturing units, knitting, dyeing and finishing on two separate decks. A logical flow of processes and communication ensures that we know where each fibre is at any time of the manufacturing process.

We can produce 20 tons of finest knitted fabrics a day.

Our design department is driving the development of new products by capturing the latest trends on the market while adding the distinct FITEX touch. It is all about perfectly merging the input from the world of creativity with the market and with the client we service.

We offer a wide range of circular knitting machines with various gauges to create the broadest possible spectrum of fabrics, thus leveraging technical and design know-how to be able to offer premium qualities: 58 circular machines for Single-Jersey, Plush, Fleece, Velvet, Rib, Interlock and faux-Furr.

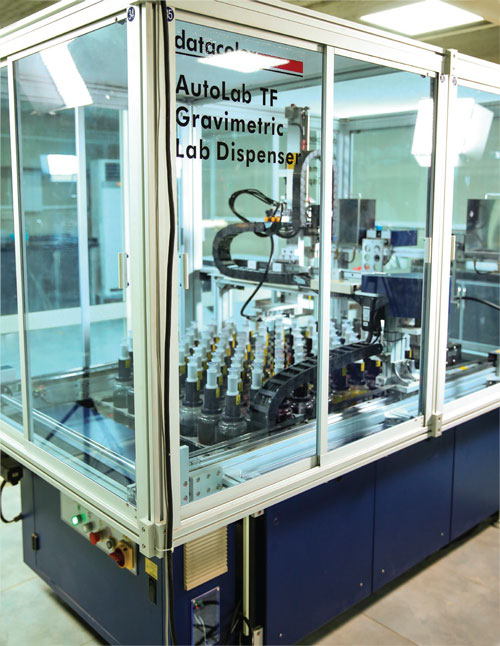

Our Dyeing and finishing unit includes a high-tech laboratory, bringing the raw fabric to life. We operate dyeing machines with various capacities (50Kg, 300Kg, 600kg, 900kg, 1.500kg) to accommodate client requirements. Technology providers such as Brückner, Lafer, Color Service and others support our in-house dyeing processes.

We never compromise on quality. Creativity and experimentation goes hand in hand with the overall goal to produce the best fabric. A powerful ERP system enables us to monitor the product throughout the full manufacturing cycle, from the fibre to the fabric. The whole team is part of the quality assurance process, all jointly working toward the best results.

We work with a wide range of natural yarns such as cotton, viscose and linen as well as with man-made yarns such as polyester or elastane. Our special treat is the application of Egyptian cotton based on Giza 70/88/90, furnishing the fabric with that unmistakable silky touch. We cooperate closely with a certified Egyptian cotton supplier.

This enables us to be as flexible as possible in the design and development of our diversified range of fabrics: Jersey, Pique, Double Pique, Interlock, Rib, Scuba, Fleece, Velour, Plush, Faux Fur and many more…

Our fabrics find their application in fashion, home-wear, underwear, sportswear or beachwear, all enjoying the highest level of comfort and wearability.

As a family business, we are concerned about the well being of all of us sharing this one planet. To operate our production in a sustainable fashion is not a claim, but a fact we practice on a daily basis. Internally and with the help of external certification programmes, we protect the human being and the environment it lives in.

Our Reverse Osmosis and filtering plant avoids the use of portable water, thus reducing the impact on a precious resource. In addition, we process and make available all the outflow water to be used in local agriculture farms.

It means for us to care about the people we work with and those wearing our fabrics. Moreover, our production is designed in a way as to protect the environment through appropriate technologies and processes.

FITEX is currently in the process of obtaining a number of key international certifications taking care of our planet and of our people.